Let's Go Way Back... (to 2001?)

I had occasion

to study high resolution photos of the prototype Crossfire and

noticed something I liked - the center caps on the wheels.

As is usually

the case when a prototype goes into production, there are things

that do not make the transition. There are many things on

the prototype that didn't make it to the production car.

Notwithstanding, it's still impressive to see how true to the

original design the final car remained.

I sat one night

and did some hunting around to find suitable parts that I might

use to recapture the design of those original center caps.

They appeared to be a large socket cap screw recessed into the

center of the cap. I grabbed one of the standard caps and

took some measures, extrapolated the dimensions of the prototype

caps, and assembled some parts I thought would come very close

to reproducing the look of the center caps on the prototype.

I played with a photo editing program to see what it might look

like on my car:

I did have to

accept the fact that the prototype center caps are dished and

have no raised center section like the production caps. I

also make a decision not to attempt to replicate the dimples

that mark each spoke near the outside rim of the center caps.

That would require a level of precision to embed little

button-head screws in a perfect circle. I didn't see

myself pulling that off. At any rate, the factory caps

have an indentation that attempts to create that effect so I am

sticking with that.

In terms of the

materials and assembly, there were two things that had to be

taken into account. I needed parts that would be light,

would take paint very well, and would not corrode. I

concluded that since this was a purely cosmetic effort, plastic

would be appropriate, and, once painted, should have the same

finish as the rest of the center cap. As long as some tire

technician didn't take an Allen wrench to them, it would be no

problem!

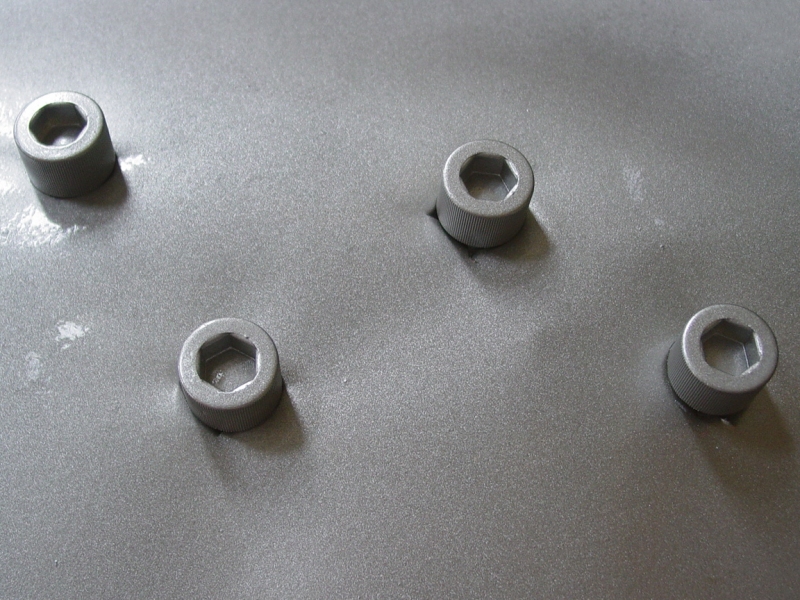

Here's the list

of parts I came up with. As I have so often done when

fabricating things from scratch, I paid

McMaster-Carr a visit and sourced everything except the

original center caps from them.

Before assembly

of the pieces, I painted the parts with a two-part treatment.

First a color coat using a carefully selected silver that

matches the color of the wheels.

First the matching silver to the wheels and center cap, making

sure that the socket of the screw is well painted and everything

has several thin coats. Next I apply a clear-coat to give

it the same luster as the wheels.

These parts are set

aside to dry for a week. That gives them enough time to

harden and fuse together. This prevents them from getting

spoiled in handling during assembly later.

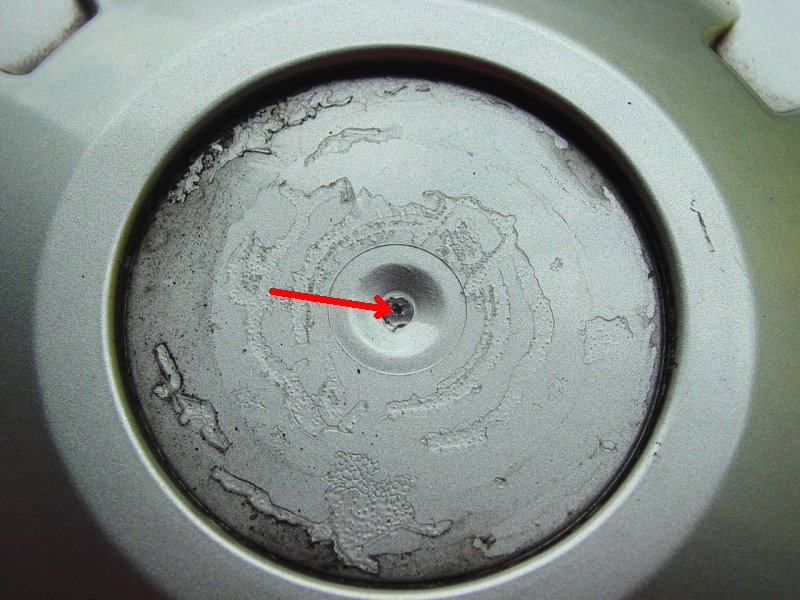

The

Chrysler logo on the center of the cap needs to be removed.

Using a jewelers flat-head screw driver, I carefully got under

the very edge of the center emblem being careful not to scratch

any part of the center cap finish.

With the edge

lifted, the glue starts to give way and I got my fingers under

the center by prying it up with my fingers. Don't use

tools because the surface underneath the emblem must not be

scratched.

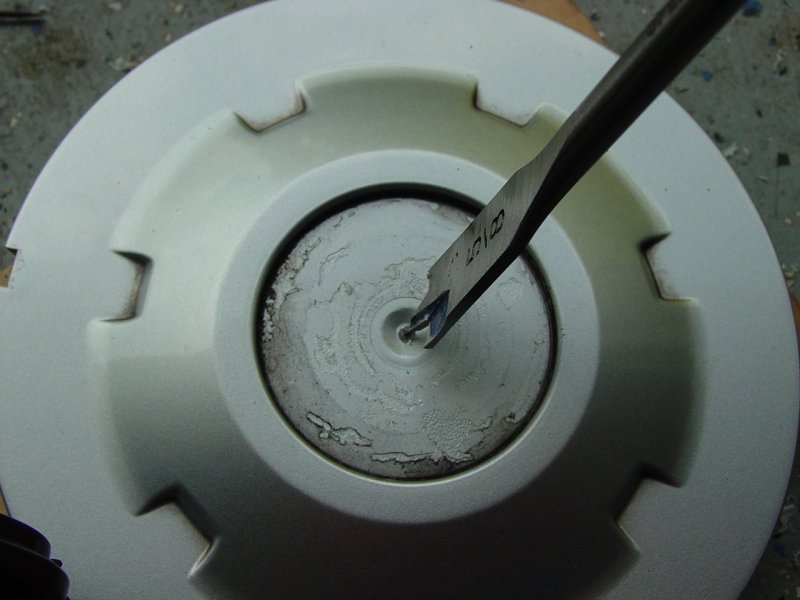

The center of the cap

is marked by the molding injection point.

I used that as

a landmark and using a spate bit, drilled a 5/8"

hole making sure it was dead center. I do not want to

introduce wheel imbalance with this project!

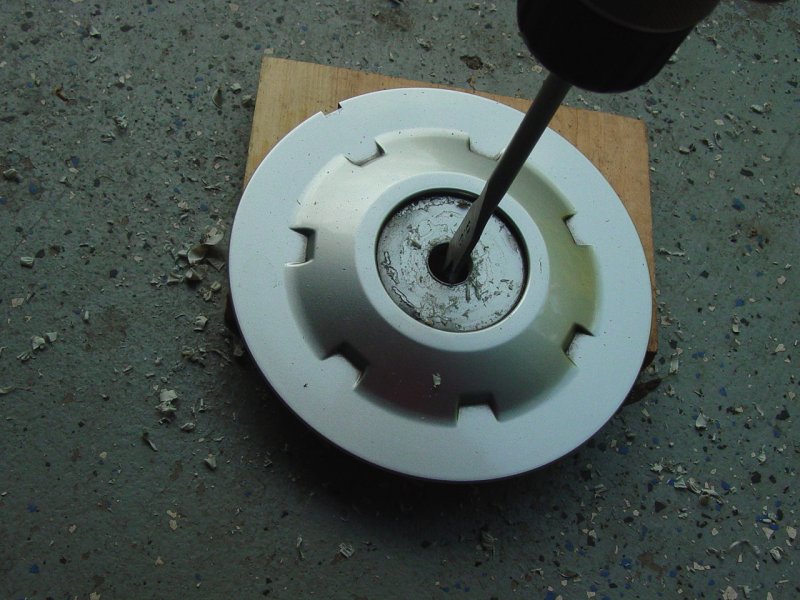

I drilled very

slowly, first scoring the cap to make sure the hole was

centered, then letting the bit slowly cut the hoe, while holding

the cap to prevent spinning.

Then, using

penetrating oil, I carefully removed the glue that once held the

center piece in place, and then cleaned out the recess

completely.

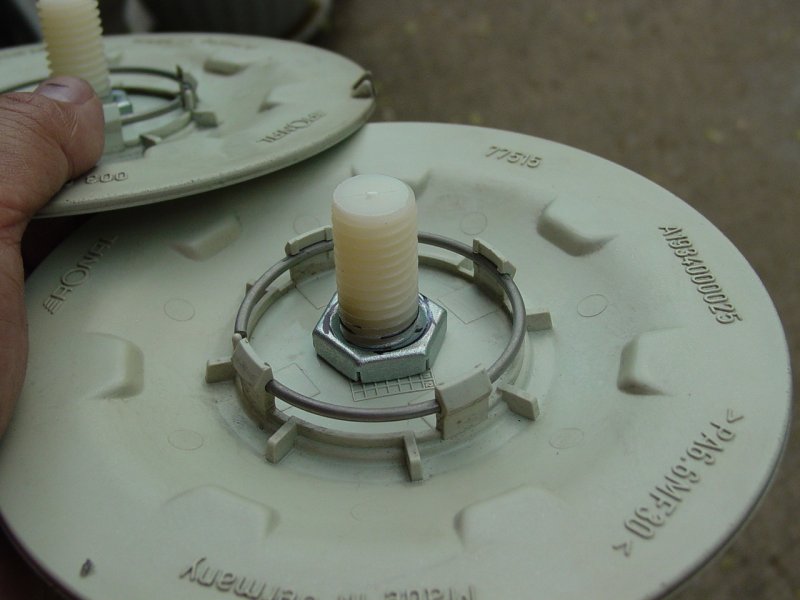

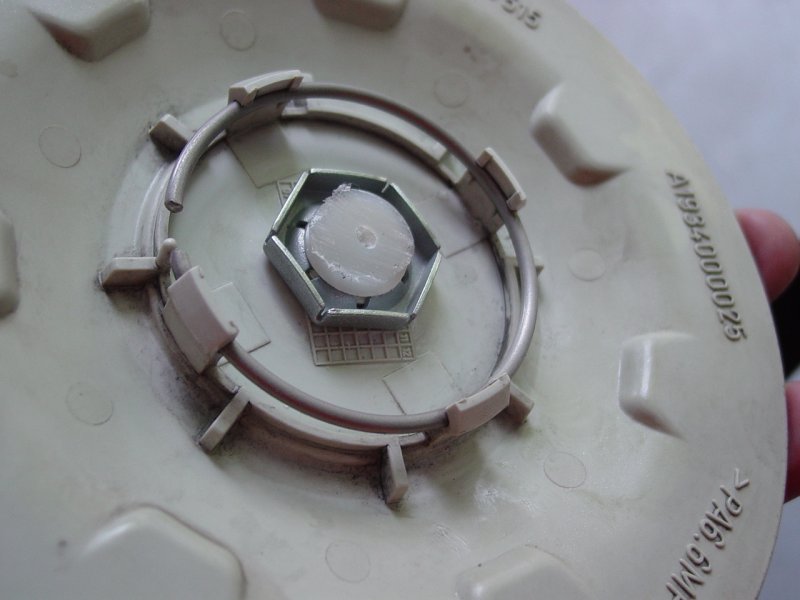

Next, I

retrieved the painted socket head cap screws, I test fitted them

into the holes. I put the retaining nut on and marked the

screw for cutting.

I cut the screw

off leaving just enough to allow threading on the nut and enough

threads to allow it to be made tight.

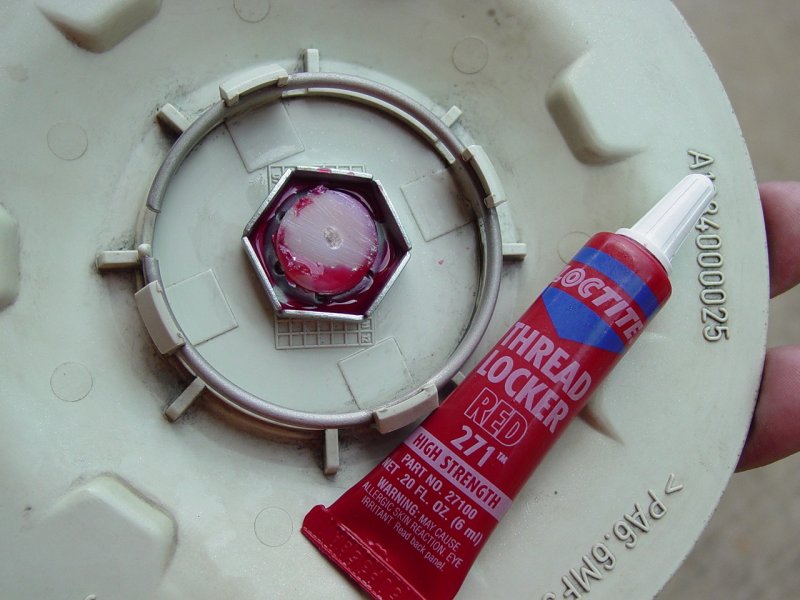

Next I

reinstalled the nut and screw, and applied some thread locking

compound to prevent the retaining nut from coming loose.

The results

approximate the look of the original prototype wheel caps.

The socket head

cap nuts are not as large as the prototype ones, but I can

revisit that should I manage to find some that large!

Visitors since

5/17/08